LBS Grooved Drum Cable Winch Drum Rope Drum Technical parameters and application. It should also be noted that drum grooves are now produced with a number of oversize dimensions and pitches.

Barton Marine Small Wincher Pair 21 641 Winches Rubber Molding Barton

An Ellington Field engineeringdesign team should make sure the Guppy Winch loads are light and infrequent.

. The double drum traction winch with a companion storage winch is commonly used with long lengths of cable. It should guide the end user through the basic design steps of a winch within the modu - lar system of Liebherr. It is composed of two parallel grooves and two crossed grooves in each circle of the winch drum.

Empty winch weights range from 300 lb. Heavy Duty LBS Groove Drum Tower Crane Winch With 100m - 10000m Rope. Yet by Federal standards a 14-inch rope may have a diameter as large as 265 inches.

Mining Groove Design With Pulling Cable or Wire Rope Reel Drum In Varied Winch Product quickly read. Assuming the rope is 7 x 19 this puts the ratio of drum diameter to wire not cable diameter at about 250. The groove pattern is engineered to suit the ropes length diameter and construction type.

For the general cavity size design removable foam inserts keep the drums secure during transport. Left or Rightas require. 02 Intention creation The company uses advanced design systems and the use of advanced ISO9001 2000 international quality management system management.

An Ellington Field engineeringdesign team should make sure that the Guppy winch system has a repeatable method to remove the slack from the wire rope adjacent to the drum sheaves. Rotation direction Main drum diametermm Main drum lengthmm Application 1 8 10 13 LefthandRighthand 430 763 The oil workover rig winch Towing winchTower crane 2 13 18 20 LefthandRighthand 623 1144 Engineering winch Lifting. As an example a grooved drum made for 14-inch rope may have a pitch of 250 inches.

Drawers and hardware cavities are common and customizable for each case. High quality Multi Functional Hydraulic Tower Crane Winch LEBS Groove Drums from China Chinas leading Multi Functional Tower Crane Winch product with strict quality control Hydraulic Tower Crane Winch factories producing high quality Hydraulic Tower Crane Winch products. You should consider whether or not to use a spiral grooved drum.

Steel Wire Rope Engineering handbook recommends a ratio of 900 for elevators. This is where loads are handled at the deck and through the surface plane. Many drum proportions result in a lesser payload capacity being available with some amount of wire paid out.

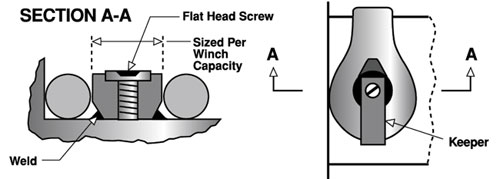

In most cases both drums are powered and have multiple grooves. Split-sleeve system consists of a pair of outer shells that are bolted or welded onto a smooth drum to provide a grooving pattern. The grooving principle of LeBus is characterised by four circumference sections.

Modern drum design embraces extensive considerations beyond the scope of this publication. It is widely used when the boats or vessels need to be carried out for repair or maintenance. 1The advantages of multilayer winding.

Many crane models have a two sided grooved drum one part of it is left the other right lay grooved. This type of winch is also ideal for launching and retrieving ships and boats. It depends on lifting height frequency of use and even the rope diameter as to the type of wire rope most suitable for that application.

These are two parallel sections PB and two crossover sections KB in which the rope is diverted by half a pitch in axial direction fig7. The angular size of the parallel and the crossover area and the grooving pitch vary from design to design. Drums Plain Smooth.

The cable is reeved from drum to drum and groove to groove providing the axial movement without producing the axial friction inherent in a single drum capstan. The drum V-groove design which is. Easy to talk with very professional and fast service the quality of winch drum is super good.

If a rope of this size were to be operated on a drum with a 250 inch pitch crowding would occur and the rope would be forced out of the groove. Live Load sum of payload drag deducts the wire weight from drum pull. Slipway winch is designed to move boats to and from the water by the slipway.

Split sleeves can be placed over smooth and ungrooved drums suitable for modification or replacement of drum. Circumstance drum-and sheave-groove tolerances should conform to the elevator manufacturers specifications. Start your homemade winch project by scrounging up a discarded manual shift car or truck transmission available from your friendly local scrap-iron dealer for.

The usual requirements for the definition of winch systems have been taken into account. 01 Strong technical team We have a strong technical team in the industry decades of professional experience excellent design level creating a high-quality high-efficiency intelligentequipment. The split sleeve is composed of spiral groove and parallel groove.

This design manual is intended to provide a broad overview into the performance spectrum of Liebherr winch systems. Ad Rugged Quality Winches Capable Of Pulling Whatever You Need Them To. The side-by-side two drum unit aboard the icebreaker Nathaniel Palmer The term Single Drum Winch can be a misnoer since two or three Load Drums can be combined on a single structure in side-by.

This prevents any slack on inner layers that can be crushed or pinched against the groove walls by outer layers. Winch drum Winch drum for electric winch- Donqi drum design Electric drum winches offering of Dongqi Dongqi electric drum winch shop mainly offering you the Engineering construction winch Marine Winch and Mine Winch with the capacity of 1-800 ton which can be customize to you application environment. When the wire rope need to wind many layers the LBS groove can fix the crossover point of the upper rope and the lower rope through crossed groove which could control the crossover point and make it finished.

The product has been received a very pleasant cooperationgood service. When first installed on the drum and during all subsequent spooling the rope must be kept under tension. Some wire ropes are more sensitive to this type of design than others.

The more obvious is the winch drums available output line pull at the full layer. This would put the drum diameter at almost 15. Cavities can be made to the drums exact dimensions or general sized cavities can be made in order to accommodate different kits.

Silvano Viola.

Crane Rope Drum For Sturdy Crane Spare Parts Of Dqcranes

Sheave And Drum Dimensions Python Wire Rope

Model Pd17 Features And Benefits Free Fall Available On Some Units Groove Drum To Help Prevent Spooling Issues Available On Some Clutch Gear Multi Clutch

Sheaves And Drums Python Wire Rope

Pulleys As Simple Machines Simple Machines Pulley Block And Tackle

Model Gh15 Features And Benefits Equal Speed Forward And Reverse Operation High Speed Reverese Available On Some Units Mult The Unit Compact Design Speed

0 comments

Post a Comment